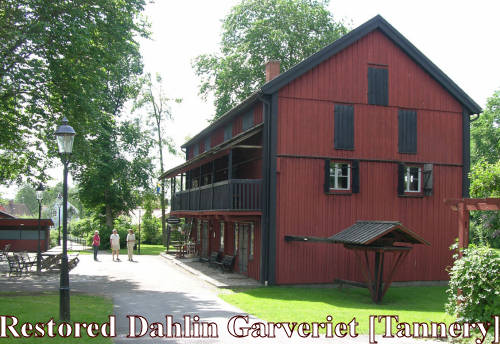

The Dahlin Family Garveriet [ Tannery]

For

anyone visiting Ljungby Sweden, the place where

Carl Dahlin and his siblings grew up, the high point of any visit has

to be the Ljungby Old Market .

For

anyone visiting Ljungby Sweden, the place where

Carl Dahlin and his siblings grew up, the high point of any visit has

to be the Ljungby Old Market .

During the 17th century the Old Market Place was the center of Ljungby.

The market would have bustled with life; it is where visiting strangers

delivered news and citizens were kept in suspense as they followed court

proceedings.

Today the Old Market Place has taken over a somewhat different setting.

A modern restaurant has taken over the innkeeper’s role but most

important the new setting contains a collection of some of the town’s

oldest buildings. These buildings give and idea what Ljungby looked like

in the early 19th century.

The center point of this complex is the Garveriet [ tannery] that Carl

Dahlin’s father Erik bought in 1891. Erik turned the business over

to his oldest son Werner who ran it for almost fifty years. When Werner

died his will left the family home and old tannery to Ljungby. Unfortunately,

the house was destroyed but that tannery was dismantled, moved and restored.

The restored tannery includes exhibits of tools and handicrafts used during

the19th century such as carpentry and boot making. An additional bonus

to a Dahlin relative is that one area on the second floor is devoted to

Werner’s younger brother Gunnar who was known through out Scandinavia

for his unique skills in restoring clocks and in particular clock faces.

A

wonderful two full-page newspaper article about the tannery was published

in 2006 in the Ljungby newspaper NÄRINGSLIV LJUNGBY—SMÅLÄNNINGEN

The article has several pictures including portraits of both Eric and

Werner Dahlin. In addition, several leather items from the Dahlin Garveriet

are also shown along with Werner’s boat.

A

wonderful two full-page newspaper article about the tannery was published

in 2006 in the Ljungby newspaper NÄRINGSLIV LJUNGBY—SMÅLÄNNINGEN

The article has several pictures including portraits of both Eric and

Werner Dahlin. In addition, several leather items from the Dahlin Garveriet

are also shown along with Werner’s boat.

A translation of this article by a Dahlin cousin Bengt Blixt [ Gunnar’s

grandson] follows. Some of article has been edited for clarity and to

focus on the Dahlin family . Headlines and manuscript follow:

The First Industry in Ljungby

The First Industry in Ljungby was

started during the early years of 1840’s

The early production of leather was replaced by another related

manufacturing product in 1925 and all production stopped almost a half

century ago. However, the building still stands although it is not in

its

original location

Introductory Text of Newspaper Article

In the teenage years of Ljungby a tanner JP Sjögren started his business.

About the same time about 10 craftsmen started their businesses . It turns

out that the tannery was counted as an industry and not a handicraft like

the others because the local government authority at the time looked upon

tanneries as an industry and entered it under that heading. During that

time period, the borderline between handicraft and industry was linked

to manufacturing process. The tannery was a special place where leather

was made and where machines were needed . Further at least some people

were employed for work.

When the tannery building was built and by whom is hard to tell. The man

known as “ The Father of Ljungby market town” Olaf Ljungcranz

owned site No. 14 located at Olofsgaten. At this site he rented a house

to the tanner Sjögren in 1841. The tanner bought the house and part

of the site in 1843.

During that time a small tannery could be operated outdoors or within

a simple building. However, for greater and more profitable production

a fairly big installation was required. Such a building was not cheap

to build and it is speculated that Olaf Ljungcranz who wanted to affiliate

businessmen to the new market town, at least lent money for the construction

of an adequate building. In 1852 the next owner Victor Theodor Schultz

bought the business. It appears that Schultz may have built the new building

at that time.

Cattle Walking

The tanner always had a lot to do. Quite a few farmers within a ten-kilometer

radius brought hides in to be made into fur or leather. The material was

used for many purposes at the time. The tanner also bought hides and often

with the help of other craftsmen made leather goods. The machinery in

the tannery was driven by cattle and referred to as “cattle walking”.

By the end of the 19th century two horses, that is, two horsepower drove

the equipment. Note: the restored tannery has a “cattle walk”

but it is not from the original Dahlin operation.

Owner Succession and operation

Schultz sold the tannery in 1861. Several others bought the business.

In 1891 Erik Gustaf Dahlin, a tanner from Nöttja bought the business

and he ran the business for fourteen years. Then in 1905 he turned it

over to his son Werner Georg Dahlin, born 1878 in Nöttja. Werner

received his vocational education in Germany and France and worked with

others in Stockholm and Växjö.

From about the year 1890 two men were employed along with the “cattle

walk”. Two lime vats and 15 tannery vats were used. The hides that

were going to be turned in to leather were put in the lime vats to loosen

the hair for final removal. The other vats contained water and spruce

or oak bark where the hides were laid. These vats were located both out

of doors and in doors. The tanning process lasted for at least six months.

.

Note: tanning is a chemical process. Nineteenth century processing at

that time often consisted of placing the hides between alternate layers

of ground tree bark [ spruce, hemlock or oak] These materials are a source

of tannic acid which is necessary to complete the chemical conversion

process. The English word for tanning is derived from the Old High German

tanna meaning oak or fir

Profitable Company

The income from the tannery up to 1904 was between 2000 and 4000 Swedish

Crowns [Sw.cr] per year

By 1906 through increased production it was 10,000 Sw.cr and in 1907 it

reached 19,250 Sw.cr. per year.

In addition to standard production, income was obtained from the manufacture

of glue and the sale of horns, hair and horsehair

The reason for the economical up turn after the turn of the century was

probably the start of clog production [wooden shoes bottoms with leather

tops*] in the tannery. A further reason for this increased profit is that

Dahlin clogs became famous for quality and comfort. Dahlin’s tannery

received several awards for leather quality with the first one probably

at the Ljungby exhibition in 1905.

. Around 1910 the old cattle walk was replaced by a steam engine of 4-7

hp. After WWI the steam engine was replaced with a 3 hp electric motor.

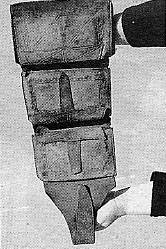

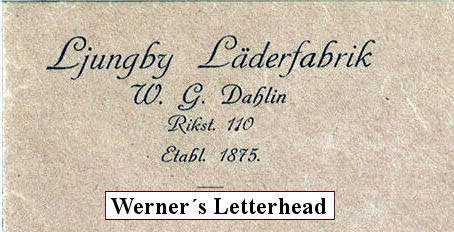

Werner Georg became a very wealthy man. He made himself a wallet and even

when it was empty it was of an enormous size.[ See unfolded wallet in

inset] In 1920 he purchased a large wooden boat that was one of the first

motor driven recreational boats on Lake Bomen.

*The wooden clog bottom was probably made by Svenssons carpentry in Ljungby

where records show they manufactured 30,000 clog bottoms in 1903.

Only Clogs

The manufacture of the popular clogs soon became the most profitable source

of the business. After the turn of the 20th century the tannery business

continued to decline in profitability and it was closed in 1925. Werner

changed the name of the business to “Ljungby leather factory”.

Werner died on the 12th of March 1954. In his obituary it specifically

mentions his cheerful and sunny temperament. His wife continued the clog

fabrication afterwards.

The next year,1955, the tannery almost burned down A fire started in an

adjacent building that manufactured hay elevators. According to the newspaper

“Smålänningen” the flames were licking the tannery

gables, but the firemen were able to save the building. Further, that

the clog business ended up sharing space with the hay-lifting business.

The newspaper article mentioned that shortly after the fire a new Ljungby

town plan called for a new street and the building of a Peoples Palace

in that location. During the 1960’s the tannery building was dismantled

and moved

The tannery was carefully taken down and stored in a dry location. It was rebuilt in the 1970’s in its present location and it is now the most valuable building in the so-called cultural reserve. “ Ljungby Old Market Place”.

On the first floor handicraft and shops are arranged. On the second floor rooms are used for the homestead museum along with other old Ljungby craftsmen tools and manufactured objects. Of course some of them are ones that Dahlin used.

This is perhaps not what the tanner Sjögren thought, 160 years ago, regarding the future of his tannery.

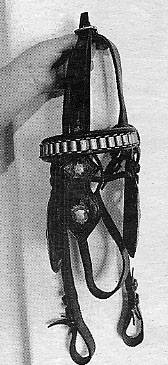

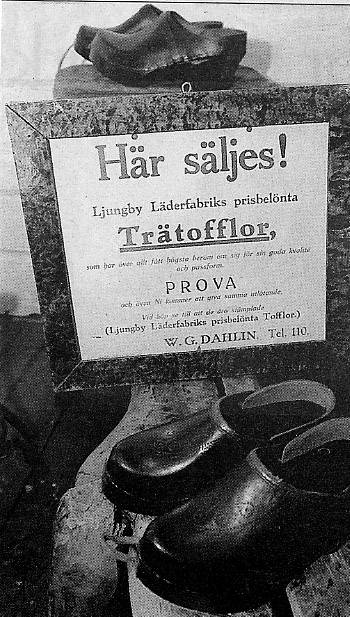

Halter manufactured

at Dahlin Factory

Newspaper photo of

Museum display

Ljungby Leather Factory’s Prize Awarded

Clogs

Which have the highest praise for good quality and fit

TRY THEM ON

And even you will give the opinion

When you buy them, see to it that they are marked

[ Ljungby Leather Factory Prize Awarded Clogs]

W.G. Dahlin: Tel.110